Introduction

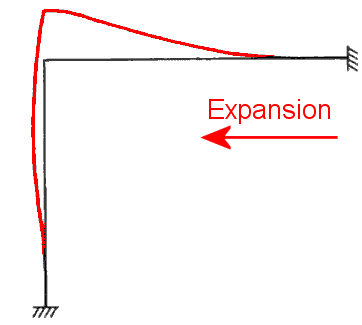

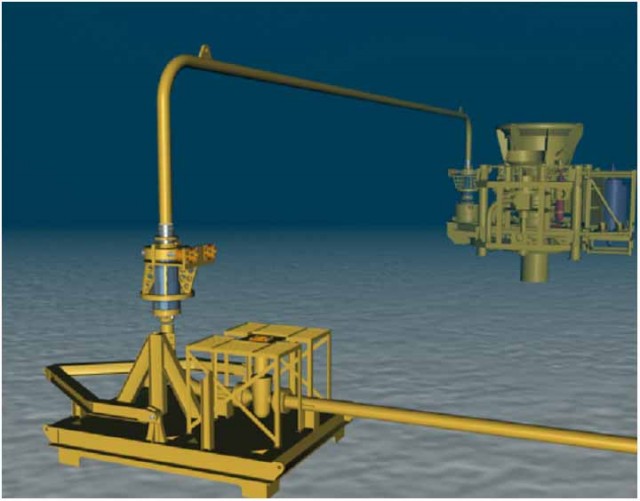

'Operational conditions (pressure and temperature) will cause expansion of the pipelines to occur. This expansion at the ends of the pipelines needs to be absorbed somehow. Usually this is accomplished with expansion spools.

The expansion spool accomodates the expansion with a 'dog-leg' with bending. The angle of the 'dog-leg' is usually 90°, and the length is designed to suit the anticipated expansions.

The design of spools is initially done by hand calculations to approximate the required size. Final design is done using finite element analysis. The finite element method allows inclusion of the required effects such as soil friction.

The axial expansion will deform the expansion spool and the associated bending will induce a lateral offset of the axis of the pipeline near the bend. Both the axial and lateral displacements should be considered when sevearl spools are in close proximity.

As bending moments are generated by the expansion, care should be taken over the positioning of flanges during design.

Short spools between structures are called 'jumpers', and are orientated horizontally or vertically.

Notable Projects

Project Name |

Project Number |

Notes |

BAOBAB |

Notable due to the Pipe in Pipe nature |

|

Greater Plutonio |

Deep Water, using SAFEBUCK | |

Qatar Gas |

KW |

Large Diameter Pipe |

Other Projects

Project Name

|

Project Number | Notes |

EPC2B |

KW 0728 |

Controlled Buckles on Existing Pipeline Crossings |

Algeria Pipeline |

KW 1071 |

Onshore |

Deep Panuke |

Codes & Standards

Company |

Title |

Doc Number / Date |

SAFEBUCK JIP |

Safe Design of Pipelines with Lateral Buckling - Design Guideline |

|

DNV |

Global Buckling of Submarine Pipelines |

DNV-RP-F110 |

DNV |

Submarine Pipeline Systems (Strain Based Limit State) |

DNV-OS-F101 |

Course Notes

Author |

Title |

Notes |

C. Sicilia |

Lateral Buckling Assessment and Mitigation Design |

|

Trevor Gee IBC |

Pipeline Course |

Books

Author |

Title |

Chapter |

Mikael Braestrup |

Design and Installation of Marine Pipelines |

6.5 |

Papers

Author |

Title |

Notes |

Hobbes, R. E. |

In-service Buckling of Heated Pipelines, Journal of transportation Engineering, ASCE, Vol. 110, No.2, March 1984, pp. 175-189 |

Approximate method for determining propensity for lateral buckling |

Taylor, N. and Gan, A. B |

Submarine pipeline Buckling – Imperfection Studies, Jour. Of Thin-walled Structures, Vol. 4, 1986, pp 295-323 |

A developed version of ‘Hobbs’, including the effects of initial OOS |

Prepared Calculations

Title / Software |

Description |

Owner / Athor |

Hobbs / Excel |

Predicts the onset of buckling |

KAJW / CSG |

Tie-In Spools