Introduction

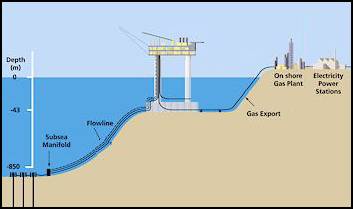

Offshore oil and gas are required to be transported to the land to be further processed and utilized; the transportation is usually carried out via a pipeline but at some instances it may not be possible to use a pipeline. For example the field may be too isolated. In these cases the alternative option is to use a transport tanker.

Pipelines are prepared onshore in sections and coated with steel reinforced concrete to weigh them down. The prepared sections can be welded together on a lay-barge. The barge slowly moves forward using an anchor system. This allows the pipeline to gently fall to the seabed and the vessel is fitted with a stinger which ensures the pipeline stays on course. Should the pipeline require trenching or burial, a suitable vessel will follow the lay-barge and either dig a trench or dump gravel on top of the pipeline

Related Subjects

Pipelines

The pipeline transporting unprocessed crude oil or gas is named (Flowline/Production line) and is usually connect between wells, platforms to the shore, where as the pipeline transporting processed oil or gas is named (Pipeline/Export line) and is usually crossing sea for distribution inside/export outside a country.

These are three types of pipeline commonly used (single pipeline, pipe-in-pipe, and bundled systems). Pipelines can be further categorized on the basis of length, diameter, material composition, manufacturing technique, water depth, etc.

Pipelines are mostly constructed using carbon steel pipes. The final choice of material, however, depends on factors like the corrosive properties of the fluid and the erosion rates predicted based on analysis of the fluid. Rigid and flexible lines are also used in subsea systems. Flexible lines are especially suitable for the design of risers and umbilicals